Beginning January 1, 2022, commercial and industrial air compressors sold or offered for sale in California are required to use the federal test procedure and must meet state standards. The federal test procedure is 10 CFR 431, Subpart T, Appendix A. The state standards are located in the California Code of Regulations (CCR), Title 20, section 1605.3(s)(2).

If clarification is needed contact the Appliance Efficiency Program.

General

The California Energy Commission (CEC) determined significant electricity and monetary savings by setting appliance efficiency standards for commercial and industrial air compressors. Standards will result in a lifecycle net monetary savings of $2,700-$9,200 per unit, and $22 million per year to California consumers. The standards will also result in a lifecycle annual electricity savings of 2,100-7,016 kilowatt hours (kWh) per unit, and 217 Gigawatt hours (GWh) per year for California consumers.

January 1, 2022

Rotary, lubricated air compressors that operate at a fixed or variable speed and use air or liquid as a cooling agent. Air compressors also must have full-load operating pressure greater or equal to 75 pounds per square inch gauge (psig) but less than or equal to 200 pounds psig.

- Docket # 18-AAER-05 for all information pertaining to the rulemaking.

- The California Code of Regulations (CCR), Title 20, section 1605.3(s)(2) for the new standards.

- Webinar: Energy Efficiency Regulations for Commercial and Industrial Air Compressors to view the CEC’s webinar for commercial and industrial air compressors.

Definitions

The definitions are located in the California Code of Regulations (CCR), Title 20, section 1602(s) and include:

- “Commercial and industrial equipment” means an article of equipment, regardless of whether it is in fact distributed in commerce for industrial or commercial use, of a type which:

- In operation consumes, or is designed to consume energy

- To any significant extent, is distributed in commerce for industrial or commercial use

- Is not a consumer product, as defined in title 20 section 1602(a)

- “State-regulated compressor” means commercial and industrial equipment that meets all of the following criteria:

- Is an air compressor

- Is a rotary compressor

- Is not a liquid-ring compressor

- Is driven by a brushless electric motor

- Is a lubricated compressor

- Has a full-load operating pressure greater than or equal to 75 psig and less than or equal to 200 psig

- Is not designed and tested to the requirements of The American Petroleum Institute standard 619, “Rotary-Type Positive-Displacement Compressors for Petroleum, Petrochemical, and Natural Gas Industries,”

- Has full-load actual volume flow rate greater than or equal to 35 cubic feet per minute (cfm), or is sold or offered for sale with a compressor motor nominal horsepower greater than or equal to 10 horsepower (hp),

- Has a full-load actual volume flow rate less than or equal to 1,250 cfm, or is sold or offered for sale with a compressor motor nominal horsepower less than or equal to 200 hp

- Is driven by a three-phase electric motor

- Is manufactured alone or as a component of another piece of equipment

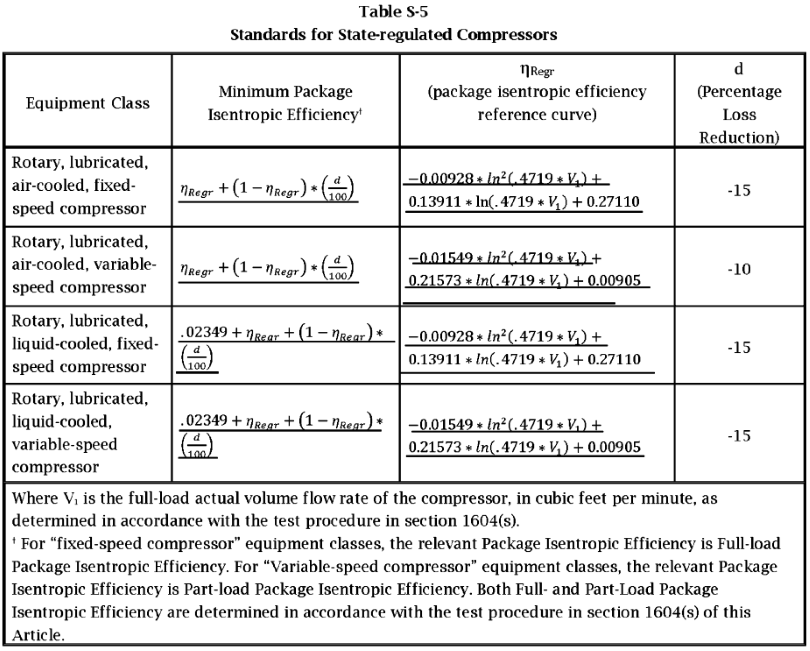

- Is one of the equipment classes listed in title 20 section 1605.3(s)(2) Table S-5

- “Basic model” of a state-regulated compressor means all units of a class of compressors manufactured by one manufacturer, having the same primary energy source, the same compressor motor nominal horsepower, and essentially identical electrical, physical, and functional (or pneumatic) characteristics that affect energy consumption and energy efficiency.

- “Air-cooled compressor” means a compressor that utilizes air to cool both the compressed air and, if present, any auxiliary substance used to facilitate compression, and that is not a liquid-cooled compressor.

- “Brushless electric motor” means a machine that converts electrical power into rotational mechanical power without use of sliding electrical contacts.

- “Fixed-speed compressor” means an air compressor that is not capable of adjusting the speed of the driver continuously over the driver operating speed range in response to incremental changes in the required compressor flow rate.

- “Liquid-cooled compressor” means a compressor that utilizes liquid coolant provided by an external system to cool both the compressed air and, if present, any auxiliary substance used to facilitate compression.

- “Lubricated compressor” means a compressor that introduces an auxiliary substance into the compression chamber during compression.

- “Positive displacement compressor” means a compressor in which the admission and diminution of successive volumes of the gaseous medium are performed periodically by forced expansion and diminution of a closed space(s) in a working chamber(s) by means of displacement of a moving member(s) or by displacement and forced discharge of the gaseous medium into the high-pressure area.

- “Rotary compressor” means a positive displacement compressor in which gas admission and diminution of its successive volumes or its forced discharge are performed cyclically by rotation of one or several rotors in a compressor casing.

Testing

The uniform test method for certain air compressors can be found in 10 CFR 431, Subpart T, Appendix A, with an allowance for alternative efficiency determination methods (AEDM) to reduce the testing burden.

The federal test method for commercial and industrial air compressors has been in effect since July 3, 2017.

Only a single unit of the appliance needs to be tested for certification purposes, except in the following instances:

- Enforcement testing may require two units to be tested if the first unit fails to meet the efficiency standards or efficiency levels reported to the Modernized Appliance Efficiency Database System (MAEDbS).

- When using the AEDM method, the U.S. Department of Energy (DOE) requires the testing of at least two units.

Efficiency Standards

The standards are located in The California Code of Regulations (CCR), Title 20, section 1605.3(s)(2) Table S-5:

Marking

California Code of Regulations (CCR), Title 20, section 1607(b) states that the following must be "permanently, legibly, and conspicuously displayed on an accessible place on each unit" of the regulated appliance:

- Manufacturer's name or brand name or trademark

- Model number

- Date of manufacture, including year and month or smaller increment