On October 1, 2020, spray sprinkler bodies sold or offered for sale in California are required to use the WaterSense test procedure (Version 1.0, September 21, 2017) and must meet state standards (California Code of Regulations, Title 20, section 1605.3(x)(1)(A)). Spray sprinkler bodies will also need to be marked per section 1607 and certified to the California Energy Commission (CEC) per section 1606 of the California Code of Regulations.

If clarification is needed contact the Appliance Efficiency Program.

General

The CEC has determined significant electricity, water, and monetary savings can be found in appliance efficiency standards for spray sprinkler bodies. These new standards will result in a first-year water savings of $88 million per year and statewide electricity savings of $8 million per year. The standards will also result in savings for water of $877 million per year and for electricity of $78 million per year for California consumers, after full stock turnover.

October 1, 2020

Yes, spray sprinkler bodies manufactured before October 1, 2020, can still be sold in California. Spray sprinkler bodies manufactured prior to October 1, 2020, are not required to be certified to the CEC’s Modernized Appliance Efficiency Database System (MAEDbS) database or meet any efficiency standards.

All spray sprinkler bodies and sprinkler bodies that do not have a way to drive the rotation of the sprinkler head, are in scope of the regulations. This includes spray sprinkler bodies and spray sprinklers.

- Docket #19-AAER-01 for information pertaining to the rulemaking.

- California Code of Regulations, Title 20, section 1605.3(x)(1)(A) for the new standards.

- Webinar: Energy Efficiency Regulations for Spray Sprinkler Bodies to view the CEC’s webinar for spray sprinkler bodies.

Definitions

The definitions are located in the California Code of Regulations (CCR), Title 20, section 1602(s) and include:

- "Spray sprinkler" means a device used to irrigate landscape that:

- Consists of a spray sprinkler body and a nozzle or orifice

- Discharges water through the air at a minimum flow rate of 0.5 gallons per minute when operated at an inlet pressure of 30 pounds per square inch or more, with the largest area of coverage available for the nozzle series using a full circle pattern

- "Sprinkler body" means the exterior case or shell of a sprinkler incorporating a means of connection to the piping system, designed to convey water to a nozzle or orifice.

- "Spray sprinkler body" means a sprinkler body that does not contain components to drive the rotation of the nozzle or orifice during operation and lacks an integral control valve. This term includes a spray sprinkler body that is a component of a spray sprinkler.

- "Nozzle" means the discharge opening, or orifice of a spray sprinkler used to control the volume of discharge, distribution pattern, and droplet size.

- "Orifice" means the emission point from a nozzle into the atmosphere.

- "Integral pressure regulator" means a device located within a spray sprinkler body that maintains constant operating pressure immediately downstream from the device, given a higher upstream pressure.

- "Landscape" means any area that is planted or installed and designed to receive irrigation, including turf grass, ground covers, shrubs, trees, flowers, and similar plant materials. Landscape does not include agricultural crops grown and harvested for monetary return.

- "Maximum operating pressure" means the highest manufacturer recommended inlet pressure to ensure proper operation.

- "Regulation pressure" means its rated outlet pressure, regardless of higher inlet pressure, as stated by the manufacturer.

Testing

The test method is the WaterSense specification for Spray Sprinkler Bodies Version 1.0, September 21, 2017.

The manufacturer is responsible for testing basic appliance models. A basic model of an appliance refers to all units of a given type of appliance (or class thereof) that are manufactured by one manufacturer, have the same primary energy source, and do not have any differing electrical, hydraulic, physical, or functional characteristics that affect energy consumption, energy efficiency, water consumption, or water efficiency. Not every spray sprinkler body or spray sprinkler model needs to be tested if the manufacturer chooses to apply the basic model definition.

Yes, test labs must be registered to MAEDbS in order to submit data. This is different than the U.S. Environmental Protection Agency WaterSense test lab process since test labs must be certified to the MAEDbS.

For information on how to submit test lab applications go to MAEDbS general instructions.

Yes, as long as they certify themselves to the CEC as a test lab.

Efficiency Standards

The new standards are located in the California Code of Regulations, Title 20, section 1605.3(x)(1)(A). Spray sprinkler bodies manufactured on or after October 1, 2020, shall meet all of the following requirements:

- Maximum flow rate at any tested pressure level. The percent difference between the initial calibration flow rate, as determined by the test method in section 1604(x)(1)(A), and the maximum flow rate at any tested pressure level, averaged for the selected samples at the test pressure levels where the maximum flow rate occurred, shall not exceed ± 12.0 percent.

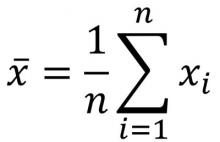

The average of the selected samples shall be calculated per the following equation:

x̄ is the average of the selected samples; n is the number of samples; and x is the percent difference between the initial calibration flow rate, and the maximum flow rate at any tested pressure level of the ith sample. Percent difference of a sample = 100 x (Qmax - Qinitial) / Qinitial. Where Qmax is the measured maximum flow rate at any tested pressure level and Qinitial is the measured calibration flow rate.

- Average flow rate across all tested pressures. The percent difference between the initial calibration flow rate, as determined by the test method in section 1604(x)(1)(A), and the flow rate at each tested pressure level, averaged across all pressure levels and all selected samples, shall not exceed ± 10.0 percent.

The average of the selected samples shall be calculated per the following equation:

- x̄ is the average of the selected samples; n is the number of samples; and xi is the percent difference between the initial calibration flow rate and the flow rate at each tested pressure level, averaged across all pressure levels of the ith sample. Percent difference of a sample = 100 x (Qaverage - Qinitial) / Qinitial. Where Qaverage is the measured flow rate at each tested pressure level, averaged across all pressure levels and Qinitial is the measured flow rate at the initial calibration point of a sample.

- Minimum outlet pressure. The average outlet pressure at the initial calibration point, as determined by the test method in section 1604(x)(1)(A), of the selected samples shall not be less than two-thirds of the regulation pressure.

The average of the selected samples shall be calculated per the following equation:

- x̄ is the average of the samples; n is the number of samples; and xi is the measured minimum outlet pressure at the initial calibration point for the ith sample.

Marking and Labeling

There are two types of marking requirements:

- California Code of Regulations, Title 20, section 1607(b) states that the following must be “permanently, legibly, and conspicuously displayed on an accessible place on each unit” of the regulated appliance:

- Manufacturer’s name or brand name or trademark

- Model number

- Date of manufacture, including year and month or smaller increment. Or, for lamps and spray sprinkler bodies, the information required by section 1607(b) shall be permanently, legibly, and conspicuously displayed on an accessible place on each unit, on the unit's packaging, or, where the unit is contained in a group of several units in a single package, on the packaging of the group.

- California Code of Regulations, Title 20, section 1607(d)(14)(A) states that each spray sprinkler body manufactured on or after October 1, 2020, shall be:

- Marked, permanently, and legibly, to indicate the presence of an internal pressure regulator

- The marking shall be on an accessible and conspicuous place on the spray sprinkler body and designed to be visible after installation

California Code of Regulations, Title 20, section 1602(a), defines “accessible place” as a place on an appliance that can be easily seen without the need for tools to remove any covering.

The date of manufacturer is the completion date of production or assembly of the appliance.

Certification

Yes, a manufacturer must certify spray sprinklers to sell or offer for sale in California. If a manufacturer intends to sell both spray sprinklers and spray sprinkler bodies, then both must be certified and appear in MAEDbS.

Yes, spray sprinkler bodies must be certified to MAEDbS to be sold or offered for sale in California.

The CEC requires certain test information to verify spray sprinkler bodies meets the appliance standard. Required data is shown in California Code of Regulations, section 1606, Table X part x.

No, the CEC does not charge a fee to certify models

Other

No, the addition of a pressure regulator would not meet the requirement that the pressure regulator is integral and within the spray sprinkler body.

See California Code of Regulations, Title 20, Section 1602 (x)(1), “Integral pressure regulator is a device located within a spray sprinkler body that maintains constant operating pressure immediately downstream from the device, given a higher upstream pressure.”